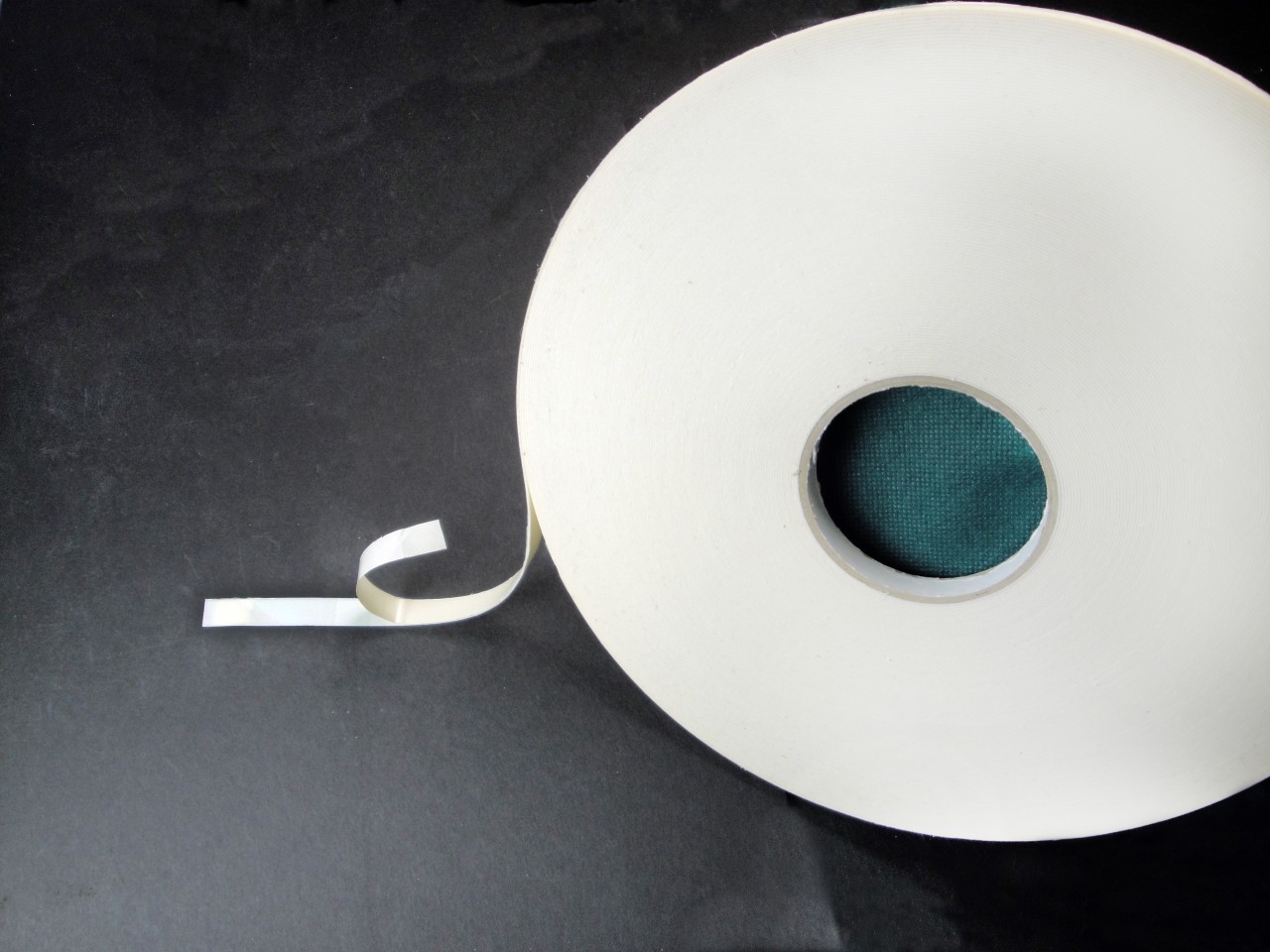

Note About Photo

Heads up! This photo shows 2" tape. Shown as an Example. You will receive the width you order.

Double Coated Polyethylene Foam Tape 1 16 in Rubber (15061)

Double Coated Polyethylene Foam Tapes

——————————-

Description:

A closed cell crosslinked polyethylene foam tape coated on both sides with high performance solvent based acrylic adhe- sive or synthetic rubber based adhesive. Excellent quick-stick sealing with high shear properties for efficient operation and secure bonding. Good resistance to humidity, mild acids, oil and grease. Excellent conformability and compressibility. Adheres well to textured and irregular surfaces. Can be easily die-cut. 3? neutral core/cartons. Available in white or black.

Application:

Used for mounting nameplates, signs, small die cast parts, mirrors, maps, etc. Used for sound and vibra- tion dampening in business machines, industrial equipment, electronic component packaging and glass panel mounts, seals, gaskets, etc. In general, the acrylic adhesive system is recommended for outdoor applications due to its higher temperature, UV, weather, chemical and plasticizer resistance. The rubber adhesive system is recommended for high shear demands as its quick grab nature is ideal for immediate load applications (mirrors) and for textured surfaces. The rubber system also exhibits higher adhesion to low-energy surfaces (some plastics, films).

Physical Properties:

Foam ? Cross-linked irradiated cellular polyethylene

Density ? 3 lbs per cubic foot

Thickness ? 1/16″ (62 mils) 1.5mm

Color ? White or black*

Tack, Adhesion (15 min dwell) ? 80 oz/in., 100 oz/in.

Shear Adhesion @ 1kg psi ? 200 hours

Release Liner ? 3.5 mil. 60# Kraft

*Double coated BLACK foam: 5%(x1.05)

Alternative to Venture #617 & #716; Scapa #SA416V & #SR516V;

Int?l Tape #316, #116, #116B & #416; IPG # 8116; Press-on P-3200R/A; 3M #4446 & #4496.

Note: The physical properties listed above are typical test results obtained from a series of laboratory tests and should not be used for the purpose of writing specifications. Before using this product, user shall determine the suitability of the product for his/her use; and user assumes all risks and liabilities in connection therewith. All test procedures used are in accordance with ASTM and PSTC methods.